Blog más reciente

Perfilado de corte por láser de PCB y FPC

Dec 27 , 2022

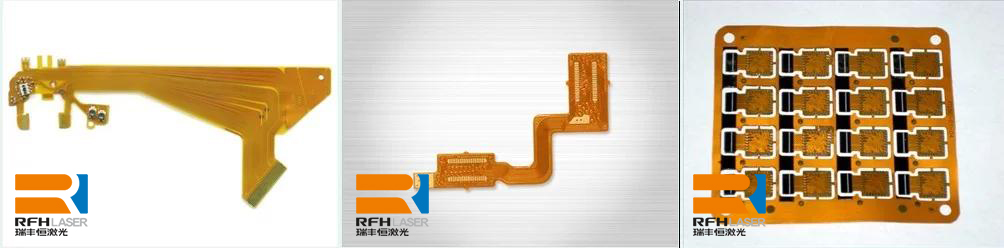

En el pasado, el desmontaje de PCB individuales de un panel de producción se ha enfrentado a una avalancha de desafíos debido al aumento de los materiales de PCB flexibles. Las técnicas de perfilado mecánico, como la puntuación en V y el enrutamiento, pueden dañar fácilmente los sustratos sensibles y delgados, creando problemas para los fabricantes de PCB que perfilan placas flexibles y rígido-flexibles. Como fabricante confiable de PCB flexibles y flexibles rígidos en China, MADPCB adopta la técnica de corte por láser durante muchos años. El corte por láser puede eliminar los efectos de la tensión mecánica que se producen durante el perfilado, como rebabas, deformaciones y daños en el circuito flexible.

Corte láser FPC

Perfilado cortado con láser de PCB flexible

Materiales flexibles cortados con láser

In the production of flex PCB and rigid-flex PCB, especially for prototypes and small batch, laser cutting will save your cost and reduces the turnarounds. In low quantity FPC fabrication, laser cut is mainly used for cutting flexible materials, including

FCCL: Polyimide (PI, also known as Kapton) and Polyester (PET) based flexible copper clad laminate (FCCL).

Adhesive: used for bonding multi-layer FCCL, PI stiffener and top side of coverlay.

Coverlay: used for covering flexible copper layers.

PI stiffeners: mechanical support or heat dissipation element.

EMI shielding film

3M/Tesa PSA (Pressure Sensitive Adhesive)

In the fabrication of Dual-Access Flex Circuits, laser cutting or laser drilling plays an role of depth-controlled drilling, which is also called Laser Depth Control. The laser beam only ablate the flexible dielectric materials and will not damage copper.

Benefits of Laser Cut

Profiling precision in the micron range.

No material fixation necessary due to vacuum table.

No flaking of material such as the case with die punching due to contact-free and force-free processing.

No knife cleaning.

No tool wear and thus, a constantly high cutting quality.

High flexibility in contour -without tool preparation or tool changes.

When Choose Laser Cut?

At MADPCB, we always consider the competitive pricing for our customer when manufacture flexible circuits. Laser cutting is ideal for close tolerance before investing in expensive punching dies. For example, small form-fit devices or ZIF connectors. Laser cut profiling provides a great way to generate pattern routed b-stage adhesive. The laser process can form a “cured” edge along the rout path of the adhesive to reduce the amount of resin squeeze-out that is released by the press lamination process.

Laser Cut Data Requirements

In laser cut processing, although most file types are acceptable, the preferred file types are Gerber, Excellon, DXF, or other 2D formats. In most cases, non-scaled data is required as MADPCB will make the appropriate scaling or offsets to meet production panel sizes.

Al cortar FPC o PCB, puede elegir el experto en láser uv de alta potencia III 355: https://www.rfhtech.com/expert-iii-355-ultra-stable-nanosecond-uv-laser-10w12w15w_p13.html