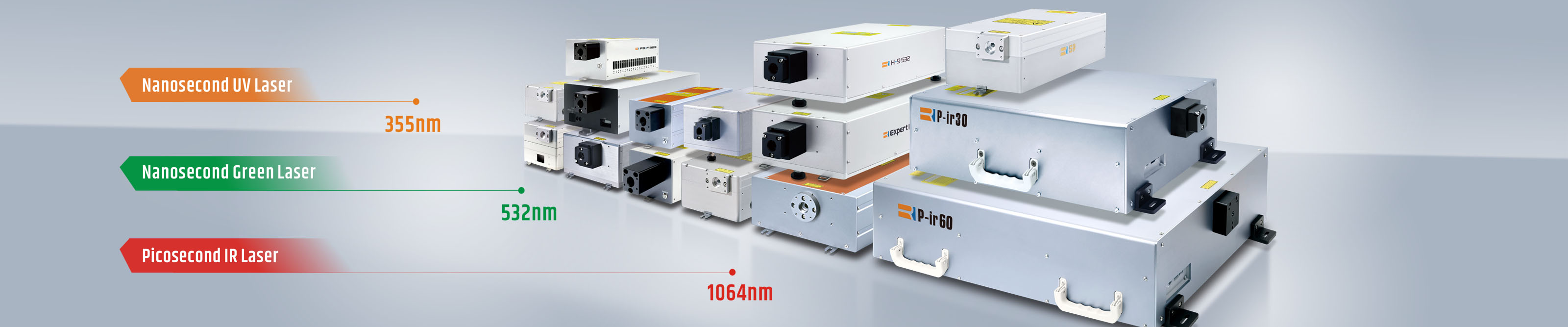

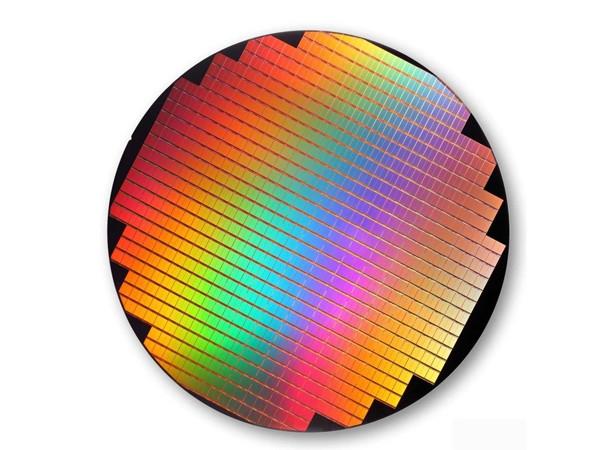

Con pulsos cortos y alta frecuencia de corte repetitivo, el láser UV RFH 355nm corta obleas

Con la mejora de la demanda en el mercado mundial de semiconductores, los equipos de semiconductores también están dando paso a nuevas oportunidades de desarrollo. Como un enlace importante en el campo de la fabricación, empaque y prueba de obleas de semiconductores, la demanda del mercado de corte por láser está creciendo gradualmente. RFH vio la oportunidad adecuada antes de esto y entró en la pista de corte por láser de semiconductores.

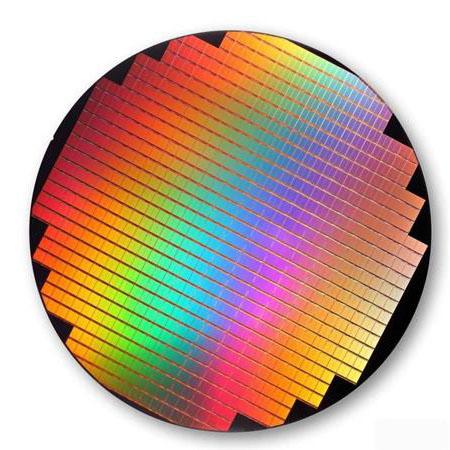

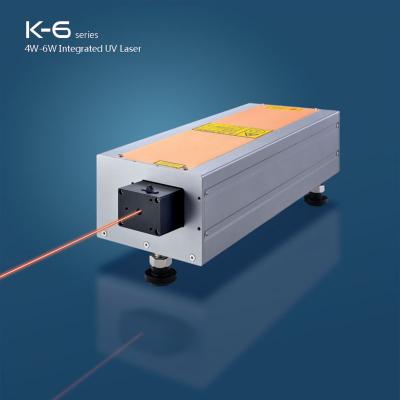

RFH 10w high-power ultraviolet laser is produced by ultra-short pulse ultraviolet technology through non-contact laser emission. The ultraviolet light emitted by it can cut the wafer with high precision without subsequent auxiliary treatment Reduced to about 0.02mm. Compared with the traditional cutting technology, RFH high-power ultraviolet laser can cut the wafer into the desired shape without adding blades or replacing consumables, and the production method that can be operated only by plugging in and installing is also greatly reduced. Cost of production.

In addition, all laser products of RFH adopt digital control technology, equipped with this high-pixel marking machine for automatic alignment, and clearly scan the parts that need to be cut to ensure the accuracy of production. In terms of cutting speed, the RFH UV laser can run stably for 24 hours. While the cutting speed is fast, there is no burr, and the smooth flying production makes the efficiency higher.

The complex international situation has put forward higher and more urgent requirements for domestic substitution. RFH occupies the market under such high pressure and high standards, and continues to provide strength for the semiconductor market.