Por qué utilizar un marcado y grabado láser UV

Feb 06 , 2023UV laser marking offers high contrast with minimal surface damage. Ideal for marking identifiers, codes, and graphics on heat-sensitive materials, metal, plastic, glass, and various organic materials.

High throughput production environments such as pharmaceuticals, beverage, and extrusion often use UV lasers for high speed marking of their products with clear, high contrast markings.

RFH’s UV lasers mark parts with readable and high contrast codes, text, and graphics for easy identification, traceability, and branding.

UV laser marking is a widely used method for manufacturers looking to mark their products with Unique Device Identification (UDI) marks.

UV Laser Markers

RFH UV LASER MACHINES

Benefit from high speed, superior coding & marking across a wide variety of materials. Ideal for marking permanent, precise, clear marks and codes onto a wide range of materials such as PET, PVC, glass, plastic, foil, metal, paper boards, paper, polypropylene, and more. UV laser marking machines are fast becoming the marking technology used by the pharmaceutical, medical, and cosmetic industries to avert counterfeiting and tampering.

UV lasers make it possible to mark materials with minimal etch depth.

High contrast, high visibility marking on many materials

Prevent back transfer marking

Minimal heat damage around the marking area

FOOD & BEVERAGE

Cans, Egg, Fruit, Plastic & Aluminum packaging film,

Aluminum pouches,

Glass Containers, PET bottles,

Plastic tubs

Laser marking on pharmaceuticals

PHARMACEUTICAL & MEDICAL

Unique Device Identification (UDI)

Medical Device Marking

Pills, Glass bottles, Plastic caps (PP)

Packaging film (PE), Silicone tubes

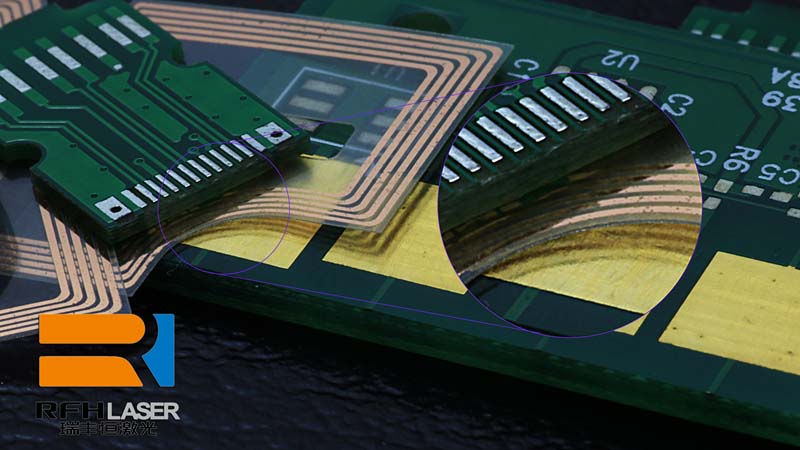

Laser marking on electronic components and PCBs

ELECTRONICS

Printed Circuit Boards, Glass epoxy substrate

Battery packs, Metal faceplates

Molded packages

High Reflectivity Materials (copper, gold and silver)

Laser marking on industrial parts

INDUSTRIAL

Cables, Extrusions, Wire, Pipe,

Tubes, Metal parts, Metal castings,

Anodized housings

Laser marking on metal and surgical instruments

METAL

Steel

Stainless steel

Painted steel

Aluminum (& anodized Aluminum)

Laser marking on plastic and rubber

PLASTIC & RUBBER

ABS

Polyamide PA

Polypropylene (PP)

Rubber, Vinyl, Teflon, Polyimide

UV lasers are ideal for marking on resin.

Laser marking on glass

GLASS

Automotive

Food

Cosmetics &Pharmaceutical

Industrial

Laser marking on wood

WOOD

Madera blanda y dura

MDF, Contrachapado, Aglomerado

corcho

Carillas

Dado que todos los materiales tienen una alta tasa de absorción para los láseres UV, la luz láser no penetra a través de materiales delgados como películas.

Marcaje láser sobre cartón

CARTULINA

Bebida

Lácteos

Farmacéutico

Embalaje general

Marcado láser sobre cerámica

CERÁMICO

Losas

Porcelana

Gres

Loza de barro

Un láser UV puede marcar sin aplicar calor, lo que disminuye la liberación de polvo y olores en el entorno de trabajo.

Marcado láser sobre espuma, ante y tejidos

CUERO Y TEJIDOS

Algodón, poliéster o fibras sintéticas

Lienzo

vellón, fieltro

Kevlar

Cuero y ante

tela de nailon