Marcado ultrafino con láseres UV y de corta duración de pulso

Dec 30 , 2022Ultrafine Marking with UV and short pulse duration lasers

Novel materials and requirements for ultra small marking challenge traditional laser technology where concerns at the micro-scale include quality of the mark to ensure a high level of readability.

Laser technology is well suited for processing difficult to mark materials including polymers, transparent materials such as glass and diamond as well as semiconductor device materials including silicon and epoxy mold compounds. In these materials, data codes as small as 50 × 50 µm can be readily processed with very high feature quality.

Advanced laser processing workstations are available in configurations optimized for high precision micro-marking. For manufacturing operations where marking or serialization is required at the same time as another micromachining step, the Dual Laser System equipped with a Laser Marking Module or other laser and scanning combination can be a highly efficient solution.

Micro Data Matrix Codes

2D Data Matrix Codes as small as 300 × 300 µm can be marked in numerous materials rapidly with IPG advanced laser process technology. It allows identification and serialization for traceability and counterfeit protection.

Die Serialization

Equipment integrated with wafer handling and automated vision systems can be used for die serialization in the semiconductor industry. UV and short pulse duration lasers allow compatibility with most materials used in backend semiconductor packaging applications. Shown here is alpha numeric marking of 1mm x 1mm die on wafer.

High precision glass marking with line widths <10 µm are generated with minimum debris. High resolution optical systems and short wavelength process avoid micro-cracking while creating a permanent mark that is impervious to chemical cleaning.

La figura muestra una retícula de alineación en vidrio ultra claro de grado de investigación.

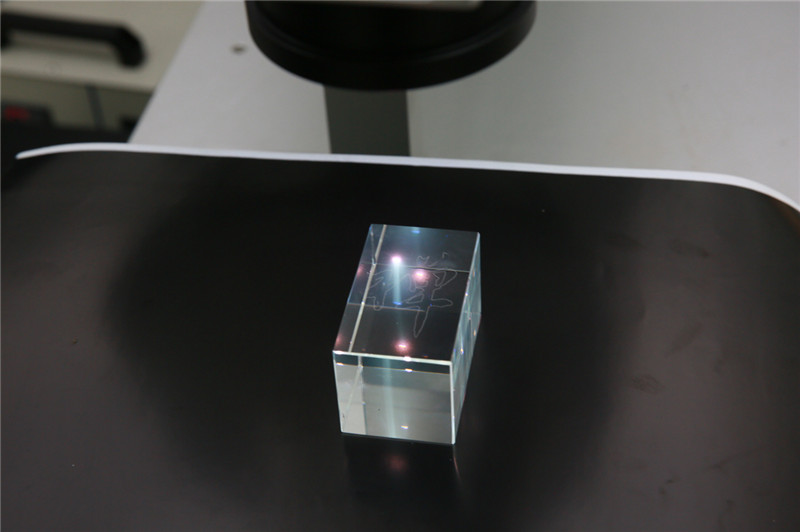

Marcado de vidrio debajo de la superficie

Permitir una marca de vidrio verdaderamente libre de desechos: el marcado debajo de la superficie en materiales altamente transparentes elimina las preocupaciones sobre la generación de desechos para aplicaciones exigentes.

Marcado de alta velocidad

Un enfoque de escritura directa funciona para escaneo de alta velocidad en áreas grandes para una variedad de materiales transparentes. El sistema utiliza escaneo de galvanómetro o el módulo de marcado láser para un proceso de marcado láser de alto rendimiento.

qué es el láser uv ultrafino: https://www.rfhtech.com/s9-uv-laser-new_c3