El cliente de RFH compra placas de circuito PCB de corte de tubo UV de 15w y 20w

Jan 11 , 2023RFH's customer buy 15w and 20w UV tube cutting PCB Circuit Boards

As a service provider for laser cutting in contract manufacturing, we have been operating successfully since 1989. We cut printed circuit boards and circuit boards from various materials efficiently, cleanly and cost-effectively.

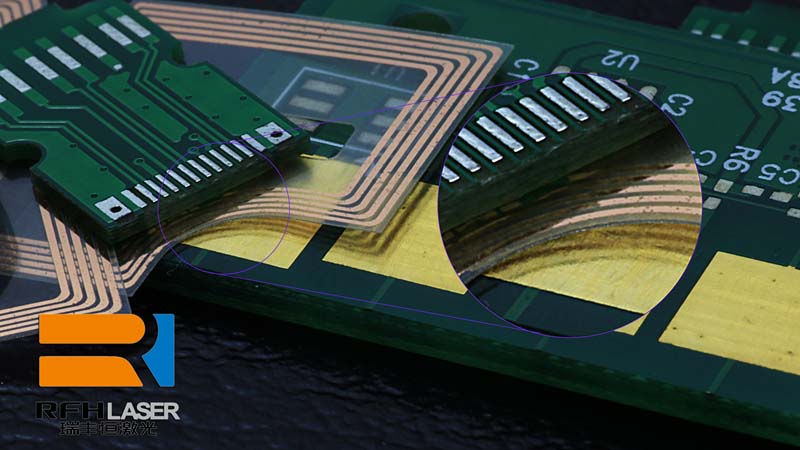

UV Laser Diode cutting PCB with reduced thermal damage

Processing of Circuit Boards With UV or USP Lasers

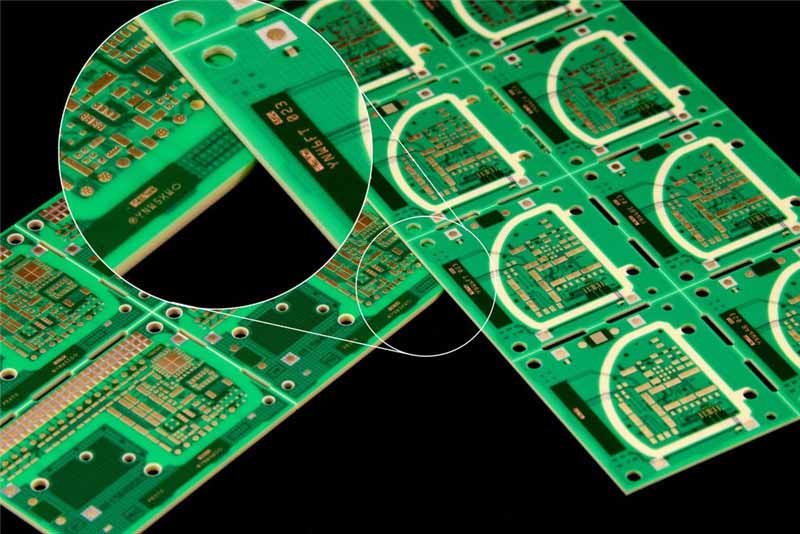

The ultraviolet (UV) laser or the ultrashort-pulse (USP) laser is a universal tool for processing of materials. The precisely focused laser beam produces ultrafine, clean contours in a wide variety of materials and circuit board types:

Multilayers

Flexible circuit boards

Rigid-flex boards

Thin rigid substrates

Tab-routed panels

HF materials

Composite materials

Innovative Laser Cutting Processes and Technologies

Cutting Through Multiple Layers

The focused laser beam reliably cuts through all layers in one or several passes and can be set to defined depths. It is suitable, e.g., for separating rigid and flexible circuit board components in multilayers or for cutting films made of thin and sensitive materials.

Material-Friendly, Noncontact Material Processing

The unpopulated materials to be processed are held in place by a vacuum table without the use of clamping tools. Due to the noncontact nature of the processing, there is no warpage, even in thin materials – this gives the process a clear advantage over milling or punching.

ESD-Compatible Carrier System

For circuit card assemblies (assembled circuit boards), an ESD-compatible carrier system that securely holds the individual panels in place during and after singulation is used. The parts are additionally protected against unintentional damage. All carriers are designed by our specialists and manufactured in-house.

No Burring

The UV/USP laser used vaporizes the material that is struck, so no burr forms. The minimal heat-affected zone prevents delamination of the material composites.

CleanCut Process

For meeting especially high demands, the so-called CleanCut process is used with a USP laser. This process guarantees the highest edge quality without smoke residues or particle buildup.

Los resultados del corte por láser son contornos precisos, casi sin radios. Los bordes cortados son suaves, verticales y limpios, incluso con las geometrías más complejas. El proceso garantiza la máxima estabilidad dimensional, calidad de borde y rendimiento.

Ventajas del corte por láser de tubos UV de 15w y 20w

Bordes de corte limpios sin rebabas ni formación de polvo

Corte de contornos extremadamente finos y cantos interiores prácticamente sin radios

Efectos térmicos mínimos, es decir, sin delaminación

Corte por láser de varios espesores de material y combinaciones en una sola operación

Singulación de placas de circuito ensambladas

No se necesita dispositivo de sujeción ni cubierta protectora

Máxima utilización de la placa porque no es necesario dejar espacio libre para cortar canales