Blog más reciente

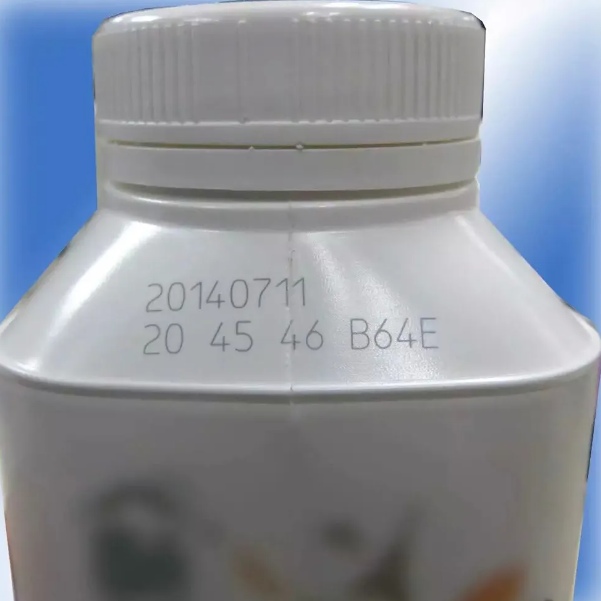

RFH Ultravioleta DPSS Láser Etiqueta de marcado UV Envasado de botellas de medicamentos

Feb 14 , 2023RFH Ultravioleta DPSS Láser Etiqueta de marcado UV Envasado de botellas de medicamentos

La razón por la que los productos farmacéuticos son diferentes de otros productos es por su naturaleza: proteger y mejorar la salud de las personas. Por lo tanto, los productos farmacéuticos no deben ser falsos desde el proceso farmacéutico hasta el proceso de envasado. El "XII Plan Quinquenal" para la industria farmacéutica se sitúa en el mismo estatus que los medicamentos, lo que demuestra la importancia del envasado de los productos farmacéuticos. La gente común no puede identificar la autenticidad de la calidad de la medicina, y solo puede identificarse por el embalaje exterior. Por lo tanto, la lucha contra la falsificación de los envases de productos farmacéuticos se ha convertido en la máxima prioridad.

The anti -counterfeiting technology on the packaging of pharmaceutical products is quite complicated, involving many fields such as optical, chemistry, physics, electromagnetics, computer technology, spectral technology, printing technology, and packaging technology. Today, the RFH laser editor will introduce a technology used in it -laser marking pharmaceutical bottle (medicinal plastic bottle).

Some people will ask, can the pharmaceutical plastic bottle be processed with laser equipment? Will it be burned? Indeed, the medicinal plastic bottle is made of PE, PP, PET and other materials. It cannot withstand high temperature burning, but this laser marking process to be introduced today is a cold processing process. Below, the RFH F-16 series 2W wind-cold ultraviolet laser is widely used in the use of medicinal plastic bottle marking processing markets to explain in detail.

The RFH S9 series 5W wind -cold ultraviolet semiconductor pump pumping solid laser, developed by the PhD team of RFH Company, has a laser special power control system (its own research and development). Functional module, ensure the stability of the laser for a long time; it also has short pulse width (<20NS@30K), superior beam quality (M2 <1.2), strict guarantee within all frequency range, and pulse width <20NS@30K, so the heat affects the area during processing is small, so that it will not burn to burn the medicinal plastic bottle, and the marking information is very delicate and beautiful, and it will not be ground.

Of course, the benefits of using RFH ultraviolet laser marking and processing pharmaceutical bottles are not only good quality and good economic effects. RFH UV laser is an integrated design. It has unique Q qi control technology, suitable for various laser application control needs, facilitates equipment integration, carried out large -scale laser marking processing and production, and high -speed assembly line processing. This is why RFH ultraviolet laser is widely used in RFH ultraviolet laser marks.

In 16 years, RFH laser has established an excellent brand image in multiple laser processing industries.