Blog más reciente

Cliente de los Países Bajos compra una fuente de láser UV RFH de 355 nm para pelado de cables médico

Dec 10 , 2022Netherlands customer buy RFH 355nm UV laser source for medical wire stripping

The 355nm ultraviolet seconds laser uses a wide range of use scenarios in the field of fine machining. According to the output power level, it is used for high -quality, high -precision marking, cutting, and drilling of the material. In recent years, 355nm ultraviolet second -second laser has frequently unlocked the skill package with cold processing characteristics. The laser peeling application of the medical product wire is one of them.

In the process of using many medical products related to RF ablation, cardiac rhythm management, etc., the materials need to be removed to reveal the metal conductor that expose the wire. And as the wire diameter is getting smaller and smaller (some wire diameter has reached the size of the hair), the positioning position involves the central and tails, etc. The conventional mechanical stripping method, such as common handmade knives to stripped the lines and laborious, cannot achieve fast and precise Selective removal, and cannot be repeatedly removed in batches.

The principle of laser peeling is to illuminate the surface of the material with high -energy density laser beams to quickly evaporate and vaporize after absorbing energy. Laser beam has high flexibility. It can set paths and remove methods in the background according to actual needs. Selectively remove the size and location that needs to be removed. Essence

Because the need for removal of materials is mostly a polymer material for thermal sensitivity, the cold processing characteristics of 355nm ultraviolet seconds laser are not allowed. It has a short wavelength, a high material absorption rate, high energy energy, and can easily interrupt the molecular bond of the material to achieve rapid peeling. This divestick is small and can be regarded as cold processing. The pulse of about 25ns, less calories, small heat accumulation, and small heat haz. By adjusting the parameters, it is not burnt, carbonized, and not melted when peeling.

For the problem of small wire diameter, peeling difficulty, 355nm ultraviolet light is easy to focus, excellent beam quality (M2 <1.2) so that the diameter of the light spots is at micron level, and the laser processing can be repetitive, so it can also be able Pay a reliable and efficient and batch -striking medical product with fine line diameter.

how to wire stripping with 355nm ultraviolet laser https://www.rfhtech.com/s9-series-3w-5w-10w-uv-laser_p9.html

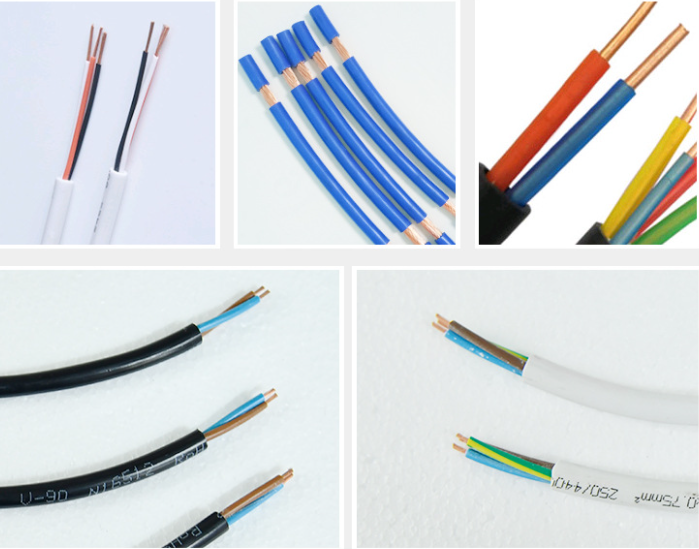

Con la profundización de la aplicación, el segundo láser ultravioleta de 355 nm no solo se puede usar en el material de alambre del producto médico, sino también en el campo de la electrónica, en el medio y al final del cable en lotes, automatizado y eficiente abra o abra la ventana para quitar la ventana. También es adecuado para láser de segundos UV de 355 nm. El pelado por láser de esta solución cambiable es una solución técnica de soporte clave indispensable para la fabricación de productos electrónicos, que se puede esperar en el futuro.