Máscara de marcado láser UV de 355 nm y termómetro de frente

Oct 20 , 2022Máscara de marcado láser UV de 355 nm y termómetro frontal

Desde el estallido de la epidemia, las máscaras y los termómetros de frente se han convertido en necesidades de la vida en esta etapa. Sin embargo, la gran brecha de demanda ha hecho que algunos comerciantes sin escrúpulos se aprovechen de ella, y una gran cantidad de máscaras inferiores han ingresado al mercado. Las máscaras falsas no solo no tienen efecto protector, sino que también tienen el riesgo de contaminación debido a la higiene del entorno de producción deficiente, que es más perjudicial para la salud personal. Para identificar máscaras reales y falsas, la forma directa es verificar las marcas láser antifalsificación.

En primer lugar, las industrias farmacéutica y médica otorgan gran importancia a la seguridad y la higiene, por lo que los requisitos para el marcado de productos son muy altos, y la información como la fecha de producción, las instrucciones de uso y otra información debe ser permanente, por lo que elegiremos el marcado láser. Máquina como marca de procesamiento, e impresora sin chorro, serigrafía y otros métodos tradicionales.

La pistola de temperatura frontal generalmente imprime el LOGOTIPO en la carcasa de plástico. El efecto del grabado láser por la máquina de marcado láser UV no se siente, y la fuente no se volverá amarilla debido a la quema, lo que puede reflejar el grado de la marca y el precio de la máquina de marcado láser UV en comparación con el marcado láser de fibra máquina, es más alto, por lo que puede reducir la probabilidad de ser falsificado y desempeñar un papel anti-falsificación.

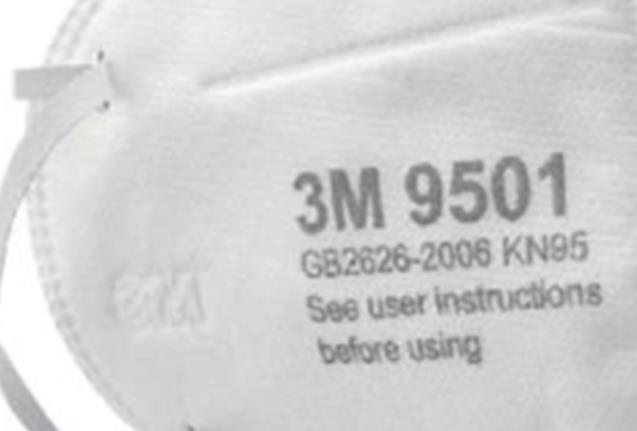

For boxed 3M N95/KN95 series masks, it can be identified by the anti-counterfeiting label on the mask box. The labels of real masks will change color from different angles, while the labels of fake masks will not change color. For bulk 3M N95/KN95 series masks, the authenticity can be identified by observing the fonts on the masks. The real 3M mask text is marked by laser, and the font has twill, while the fake is printed by ink and has dots (traces of uneven ink).

Why laser: the characteristics and application advantages of laser marking anti-counterfeiting

The basic principle of laser marking is to use a laser beam with high energy density to act on the surface of the material, to instantly vaporize or change the color of the surface material by focusing, and to form the required permanent image by controlling the path of the laser on the surface of the material. Text mark. Since laser marking can print various characters, symbols and patterns, the size of the characters can be from millimeters to microns, which has special significance for the anti-counterfeiting of products, so it is widely used in the anti-counterfeiting market.

Before the large-scale application of laser marking, the marking on packaging was usually printed with ink. The marks printed by this traditional method tend to peel off over time, become blurred, easily tampered with, and cannot be processed with high precision. Although it has advantages in equipment cost, consumables (ink) continue to cost more and cause some pollution to the environment.

Taking common food packaging as an example, because the marks printed by traditional methods are easy to erase and fall off, some criminals will print some expired or even counterfeit products with brand trademarks, or modify the production date, so that these substandard products can be circulated. in the city. Such phenomena are common in the fields of grain and oil, beverages, snacks, sauces and so on. In addition, for some paper food packaging, the harmful substances of ink may penetrate the packaging and contaminate the food, posing a threat to the health of consumers.

The emergence of laser technology has solved a series of problems brought by traditional ink printing. For food packaging, the use of laser marking has the advantages of non-toxic, non-polluting, high efficiency, high definition, exquisite patterns, and permanent shedding. In addition, laser marking can also be combined with computer technology. By linking to the database system, we can track and inquire about the detailed information of the factory and circulation of food in time to ensure that we can eat with confidence.

The medical industry is inseparable from the escort of laser marking. Since medical products are in direct contact with the human body, it is related to the life and health of the people, so the prevention of counterfeiting and anti-counterfeiting of medical products has become the top priority of protecting the health and safety of consumers.

In addition to some of the features mentioned above, the marking of medical devices and pharmaceuticals has some special requirements. For example, for common pills and soft capsules, if lithographic printing is used, the product will be stressed, while non-contact laser marking will not deform the capsule, and can mark smaller information on tiny pills. On medical devices such as stainless steel surgical and dental equipment, the laser can mark absolutely smooth surfaces, which prevents bacteria from adhering to the surface, and the marked surface does not damage the corrosion-resistant chemical passivation treatment , allowing the anti-corrosion coating to persist even after years of use and countless cleanings and sterilizations. Another example is the 3M mask mentioned at the beginning, whether there is a laser mark is an important sign to distinguish the authenticity.